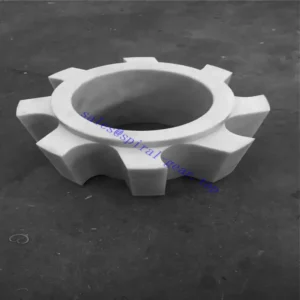

Low carbon steel forging large crown gear large spiral bevel gear

As one of the spiral gear manufacturers, suppliers, and exporters of mechanical products, We offer spiral gear and many other products.

Please get in touch with us for details.

Mail:[email protected]

Spiral Gear

Spiral gears are a type of mechanical gear that are designed to transmit power and motion between two rotating shafts at an angle. They are commonly used in a variety of industrial applications, including automotive, aerospace, and manufacturing, where precise and efficient power transmission is required.

One of the key benefits of spiral gears is their ability to operate smoothly and quietly, even at high speeds and under heavy loads. This is due to the unique design of the gear teeth, which are cut in a helical pattern rather than straight across the gear face. This helical pattern helps to distribute the load more evenly across the gear teeth, reducing the amount of noise and vibration that is generated during operation.

Another advantage of spiral gears is their high efficiency, which is the measure of how much of the power input is actually transmitted to the output. Spiral gears have a higher efficiency than many other types of gears because the helical teeth allow for a larger contact area between the gears, which reduces the amount of sliding friction and increases the amount of rolling friction. This means that more of the power input is used to turn the output shaft, rather than being lost as heat due to friction.

Spiral Gear Technical Parameters

|

Materia

|

Carbon Steel , Alloy Steel

|

|||

|

Structure

|

Forging , Casting and Welding

|

|||

|

Module of Gear

|

8-120

|

|||

|

Gear Grinding

|

MAX Module 24

|

|||

|

Diameter of Gear Wheel :

|

MAX 13 000 mm

|

|||

|

Diameter of Spiral Gear :

|

MAX . 2 200 mm

|

|||

|

Length of Gear Shaft :

|

MAX 5 000 mm

|

|||

|

OEM Service Offered

|

According to Customer Drawings

|

|||

|

Heat Treatment

|

Q & T Case Hardening

|

|||

Spiral Gear Benefit

Smoother operation: The spiral teeth of spiral gears mesh gradually, which helps to reduce vibration and noise. This makes them ideal for use in applications where quiet operation is important, such as in cars and other vehicles.

Higher efficiency: The spiral teeth of spiral gears also provide a higher level of efficiency than straight-cut bevel gears. This is because the spiral teeth engage over a greater portion of their surface area, which reduces friction and heat generation.

Greater strength: The spiral teeth of spiral gears are also stronger than straight-cut bevel teeth. This is because the spiral teeth are more resistant to bending and fatigue.

We are one of the best spiral gear suppliers. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!