Product Description

We Are Precision Metal Parts Manufacturer And We Providing Custom Processing Service. Send Us Drawings, We Will Feedback You Quotation Within 24 Hours

Precision Parts Display

Click Here Get More Information

Our Advantages

Equipment

3-axis, 4-axis and full 5-axis processing equipment, CNC lathe, centering machine, turning and milling compound, wire cutting, EDM, grinding, etc

Processing

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

Materials

Aluminum, metal, steel, metal, plastic, metal, brass, bronze, rubber, ceramic, cast iron, glass, copper, titanium, metal, titanium, steel, carbon fiber, etc

Tolerance

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

Quality Assurance

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

Tolerance

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment |

Machining Workshop

Production Process

Quality Guarantee

Click Here Get Free Quotation

Application industry

CNC Machining Parts Can Be Used in Many Industry

Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries, Instruments & Meters, Office equipments, Home appliance, Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc

Areospace

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons, Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears,Differential Housing, Axle Shafts

Auto&Motorcycle

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons,Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears, Differential Housing, Axle Shafts

Energy

Drill Pipes and Casing, Impellers Casings, Pipe Control Valves, Shafts, Wellhead Equipment, Mud Pumps, Frac Pumps, Frac Tools,Rotor Shafts and disc

Robotics

Custom robotic end-effectors, Low-volume prototype, Pilot, Enclosures, Custom tooling, Fixturing

Medical Industry

Rotary Bearing Seal Rings for CHINAMFG Knife,CT Scanner Frames,Mounting Brackets,Card Retainers for CT Scanners,Cooling Plenums for CT Scanners,Brackets for CT Scanners,Gearbox Components,Actuators,Large Shafts

Home Appliances

Screws, hinges, handles, slides, turntables, pneumatic rods, guide rails, steel drawers

Certifications

FAQ

Q1. What kind of production service do you provide?

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Simple Assembly and Various Metal Surface Treatment.

Q2. How about the lead time?

Mould : 3-5 weeks

Mass production : 3-4 weeks

Q3. How about your quality?

♦Our management and production executed strictly according to ISO9001 : 2008 quality System.

♦We will make the operation instruction once the sample is approval.

♦ We will 100% inspect the products before shipment.

♦If there is quality problem, we will supply the replacement by our shipping cost.

Q4. How long should we take for a quotation?

After receiving detail information we will quote within 24 hours

Q5. What is your quotation element?

Drawing or Sample, Material, finish and Quantity.

Q6. What is your payment term?

Mould : 50% prepaid, 50% after the mould finish, balance after sample approval.

Goods : 50% prepaid, balance T/T before shipment.

| Type: | Customized |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Customized |

| Material: | Carbon Steel |

| Power Source: | Customized |

| Weight: | Customized |

| After-sales Service: | No |

| Samples: |

US$ 0.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

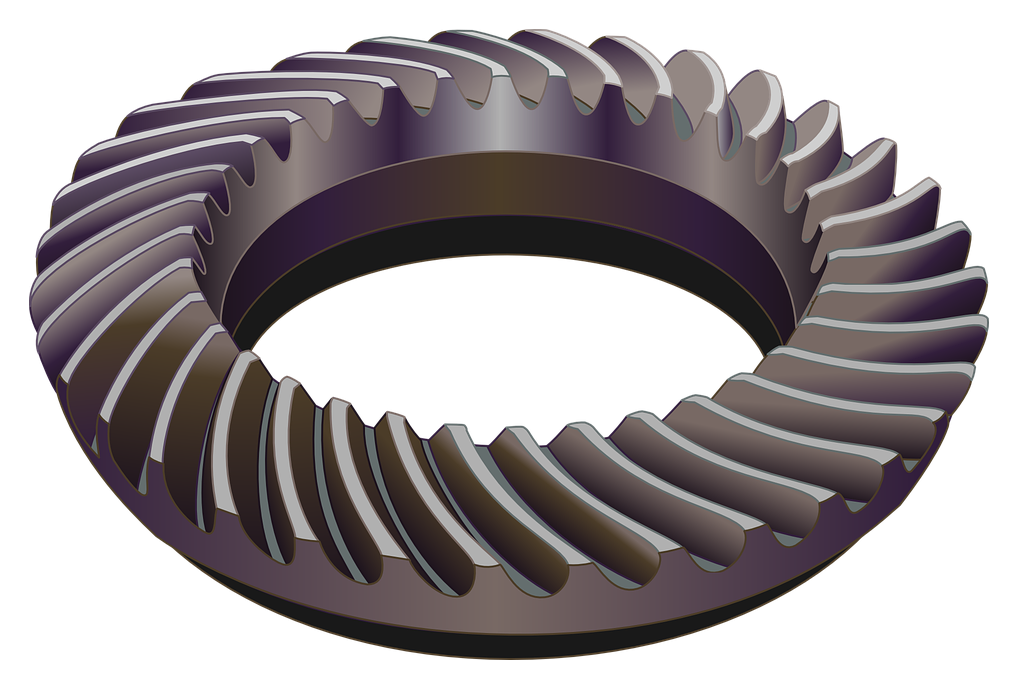

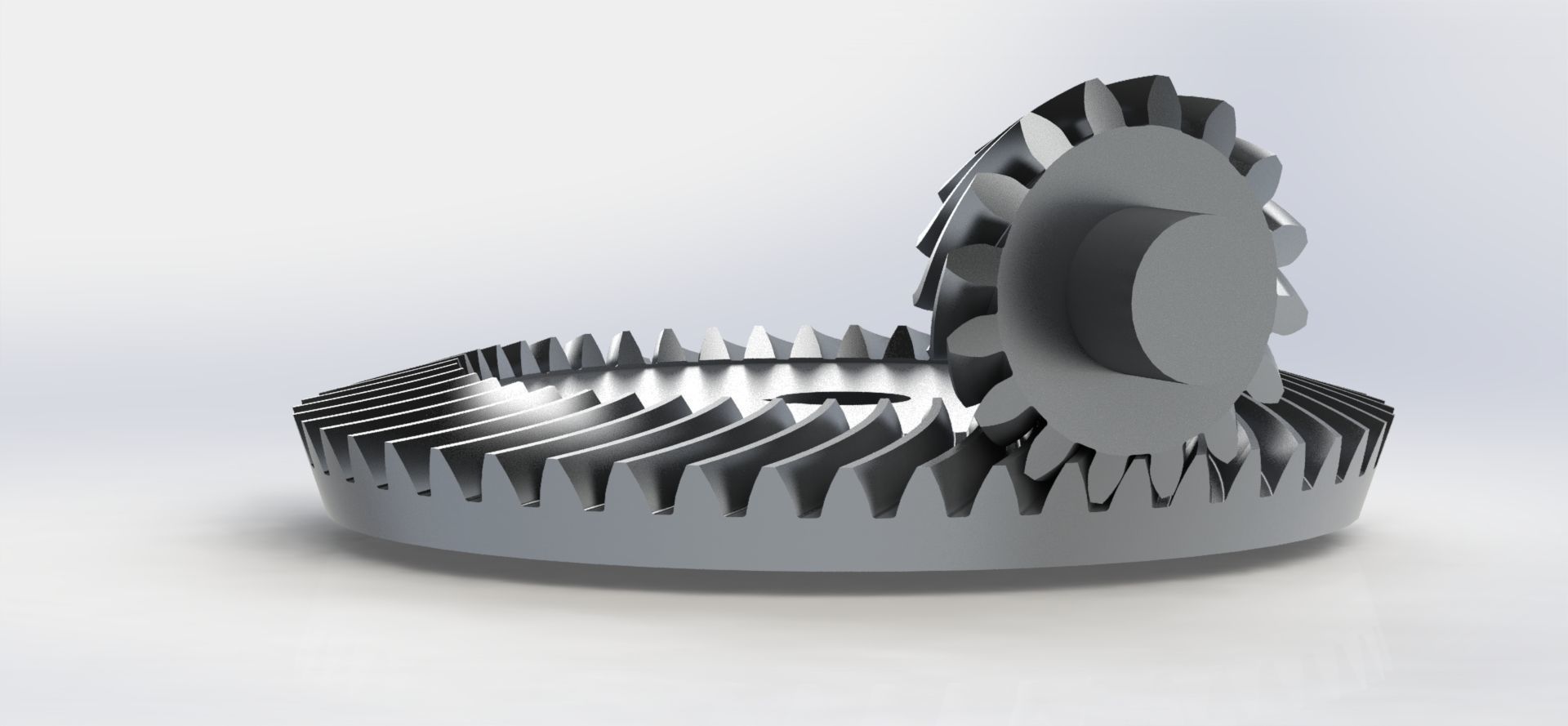

How do spiral gears handle variations in tooth engagement during operation?

Spiral gears are designed to handle variations in tooth engagement during operation effectively. The unique helical tooth arrangement of spiral gears allows them to accommodate these variations and provide several benefits. Here’s how spiral gears handle variations in tooth engagement:

- Gradual Engagement: One of the key advantages of spiral gears is their ability to achieve gradual tooth engagement. As the gears rotate, the helical shape of the teeth allows them to come into contact gradually, starting from one end of the gear to the other. This gradual engagement minimizes the impact and shock that would occur with sudden full tooth contact in other gear types. It results in smoother and quieter operation, reducing noise, vibrations, and stress on the gear system.

- Increased Tooth Contact Area: Spiral gears provide a larger tooth contact area compared to straight-cut or spur gears. The helical tooth profile extends the contact length along the gear face, distributing the load over multiple teeth at any given moment. This increased contact area enables spiral gears to handle higher loads and transmit torque more efficiently.

- Load Sharing: Due to the helical arrangement, spiral gears naturally distribute the load across multiple teeth. This load-sharing characteristic helps to minimize tooth wear and fatigue. As the gears rotate, different teeth come into contact, ensuring that the load is distributed evenly. This load sharing capability enhances the gear system’s durability and extends its service life, particularly in applications with fluctuating loads.

- Reduction of Side Thrust: Spiral gears generate an axial thrust force during operation. However, by using pairs of spiral gears with opposite helix angles, this side thrust force can be greatly reduced or even eliminated. When paired gears with opposite helix angles mesh together, the axial thrust forces cancel each other out. This eliminates the need for additional thrust bearings or complex gear arrangements to counteract the axial forces, simplifying the gear system design.

- Improved Lubrication: The helical tooth profile of spiral gears promotes better lubrication. The continuous sliding motion between the teeth creates a pumping action that helps distribute lubricant along the tooth surfaces. This improved lubrication reduces friction, heat generation, and wear, enhancing the overall efficiency and longevity of the gear system.

These features of spiral gears—gradual engagement, increased tooth contact area, load sharing, reduction of side thrust, and improved lubrication—make them highly effective in handling variations in tooth engagement during operation. Spiral gears are commonly used in various applications such as automotive transmissions, industrial machinery, and power generation systems, where smooth and reliable power transmission is crucial.

Can spiral gears be used in precision machinery and equipment?

Yes, spiral gears can be used in precision machinery and equipment with excellent results. They offer several advantages that make them well-suited for such applications. Here’s why spiral gears are suitable for precision machinery and equipment:

- Smooth Operation: Spiral gears provide smooth and precise gear operation. The helical tooth arrangement ensures gradual tooth engagement, resulting in reduced impact, vibration, and noise. This smooth operation is crucial in precision machinery where precise movements and low noise levels are required.

- High Load Capacity: Spiral gears have a high load-carrying capacity, allowing them to handle heavy loads encountered in precision machinery. The helical tooth profile distributes the load across multiple teeth, reducing stress concentration. This feature enables spiral gears to transmit torque efficiently and withstand the forces associated with precision applications.

- Efficient Power Transmission: Spiral gears offer efficient power transmission, minimizing energy losses and optimizing overall system efficiency. The helical tooth profile reduces sliding friction, resulting in improved power transmission efficiency. This efficiency is particularly important in precision machinery where energy conservation and high performance are critical.

- Reduced Noise and Vibration: Spiral gears exhibit reduced noise and vibration due to their gradual tooth engagement and improved contact pattern. This feature is highly desirable in precision machinery, where noise reduction is essential for maintaining a quiet working environment and ensuring accurate operation.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears to cancel out axial thrust. This axial thrust compensation simplifies gear design and reduces the need for additional components such as thrust bearings. It is particularly advantageous in precision machinery, where precise axial movement and minimal axial forces are desired.

- Reliability and Durability: Spiral gears are known for their reliability and durability. The gradual tooth engagement, load distribution, and reduced friction contribute to their long-term performance under demanding conditions. Precision machinery requires gears that can withstand continuous use and maintain high precision over time, making spiral gears a suitable choice.

Considering their smooth operation, high load capacity, efficient power transmission, noise reduction, axial thrust compensation, reliability, and durability, spiral gears are well-suited for precision machinery and equipment. They can contribute to the overall performance, accuracy, and longevity of precision systems.

How do spiral gears contribute to smoother and quieter gear engagement?

Spiral gears, also known as helical gears, offer several design features that contribute to smoother and quieter gear engagement compared to other gear types. Here’s how spiral gears achieve this:

- Gradual Tooth Engagement: The helical tooth arrangement in spiral gears allows for gradual tooth engagement as the gears mesh. Unlike straight-cut gears, where the teeth make sudden contact, spiral gears have angled teeth that come into contact gradually. This gradual engagement helps to reduce impact and noise during gear meshing.

- Increased Contact Ratio: The helical tooth design of spiral gears provides a higher contact ratio compared to straight-cut gears. The contact ratio refers to the number of teeth in mesh at any given time. With a higher contact ratio, the load is distributed over multiple teeth, resulting in reduced stress on individual teeth and smoother gear operation.

- Reduced Sliding Friction: The helical tooth arrangement in spiral gears helps minimize sliding friction between the teeth. As the teeth mesh, the angled surfaces slide against each other instead of making direct contact. This sliding action reduces friction and wear, leading to smoother operation and reduced noise levels.

- Efficient Load Distribution: Spiral gears distribute the load over multiple teeth due to their helical tooth arrangement. This distribution of load helps to evenly distribute the forces and minimize localized stresses. By spreading the load, spiral gears can handle higher torque transmission and carry heavier loads, resulting in smoother and more reliable gear engagement.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears. This configuration helps cancel out the axial thrust generated during gear meshing. By eliminating or reducing the axial thrust, spiral gears reduce the need for additional thrust bearings and simplify the gear design, contributing to smoother operation.

These design features of spiral gears, including gradual tooth engagement, increased contact ratio, reduced sliding friction, efficient load distribution, and axial thrust compensation, work together to provide smoother and quieter gear engagement. These characteristics make spiral gears ideal for applications where noise reduction, smooth operation, and reliable gear meshing are essential.

editor by CX 2023-10-12